Anchorage alternative to hook bars and long development length

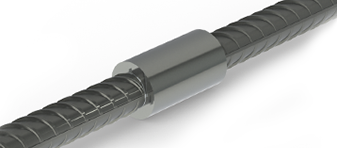

Headed Bars are a simple and effective alternative to hooks and long development length.

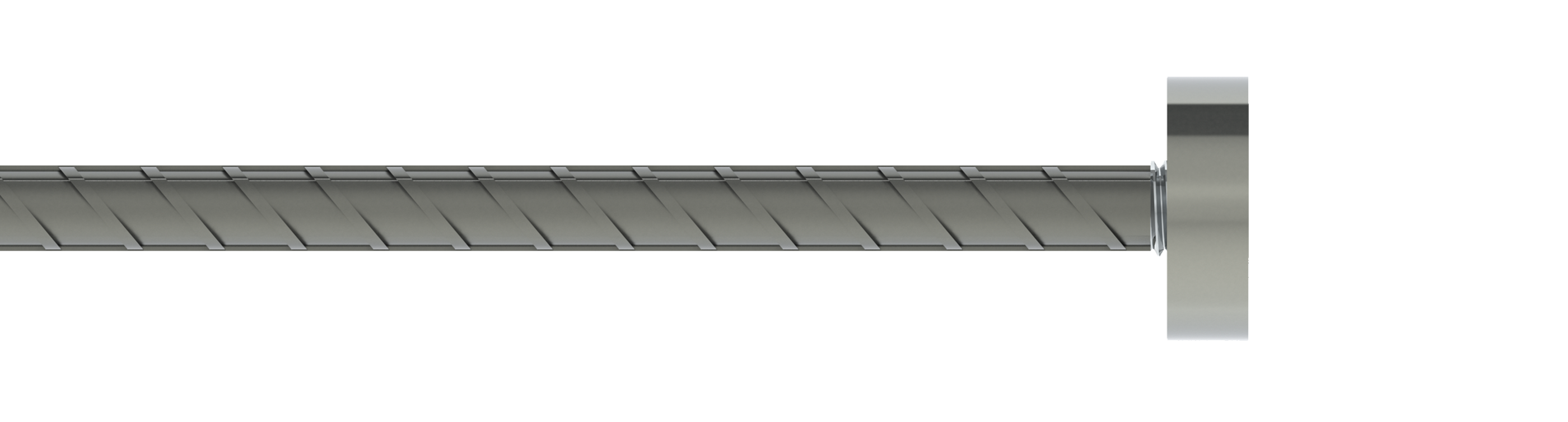

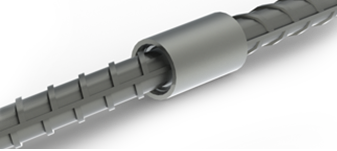

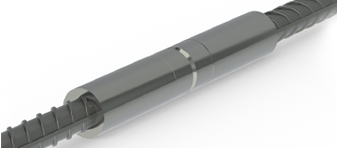

A compact disc is mounted onto the reinforcement bar end. The assembly of the rebar and the anchor provides a anchorage superior to long straight or bent reinforcement bars, while being simpler and faster to install.

Headed Bars contribute to reducing rebar congestion in heavily reinforced area, which ultimately eases the compaction process and result in better concrete quality in key areas of the structure.