Precast element connection made easy!

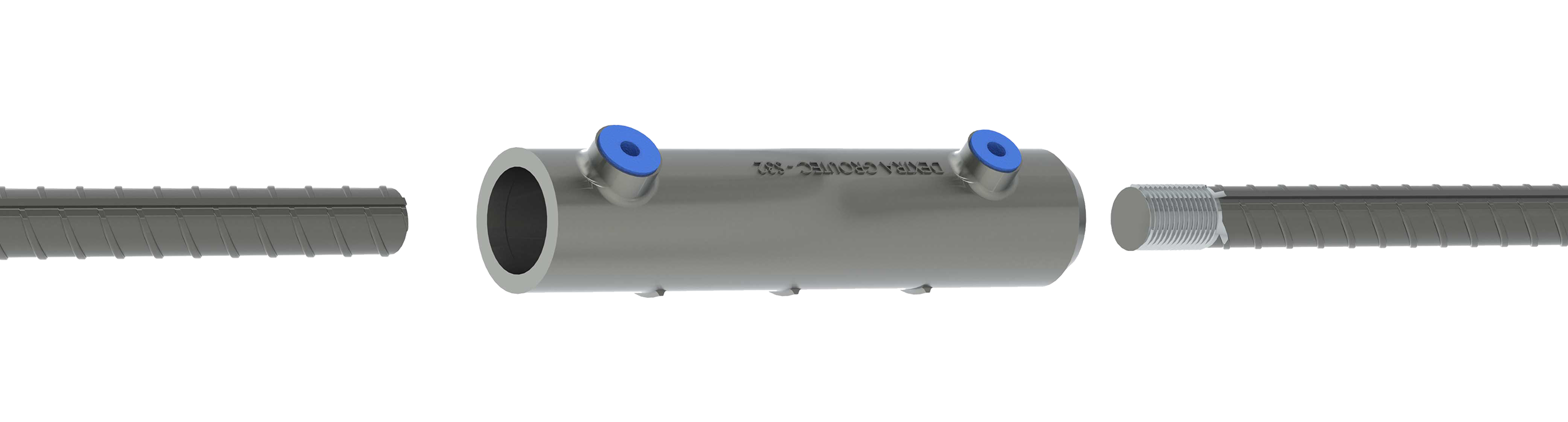

Groutec S is a mechanical splicing designed for the connection of precast elements.

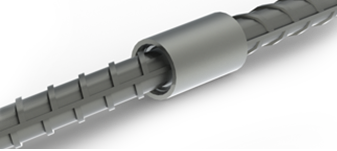

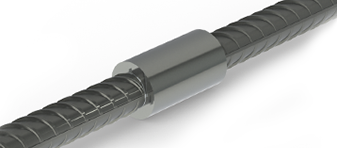

Each Groutec sleeve features a threaded end used for the connection to reinforcement at the precast factory and a cavity to perform a grout connection at site.

Groutec S is designed and manufactured in compliance with Eurocode 2, BS 8110, ACI 318, IBC, AASHTO.