Active Anchors

Active Anchors

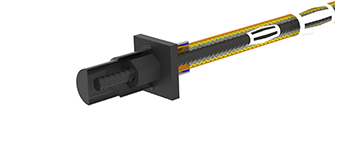

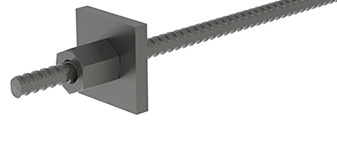

FRP post-tensioned anchoring solution

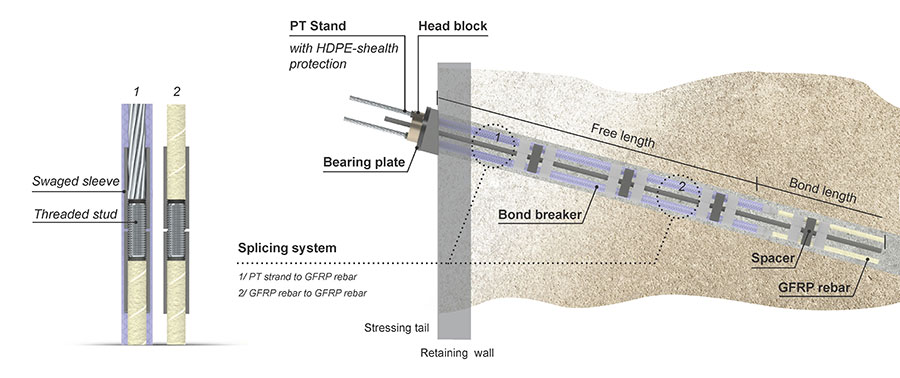

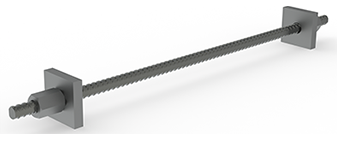

An Active Anchors is post-tensioned from the external face of the ground immediately after installation, and is usually designed to help prevent deformation of the ground or retained structure. It has a free length and a bonded length.

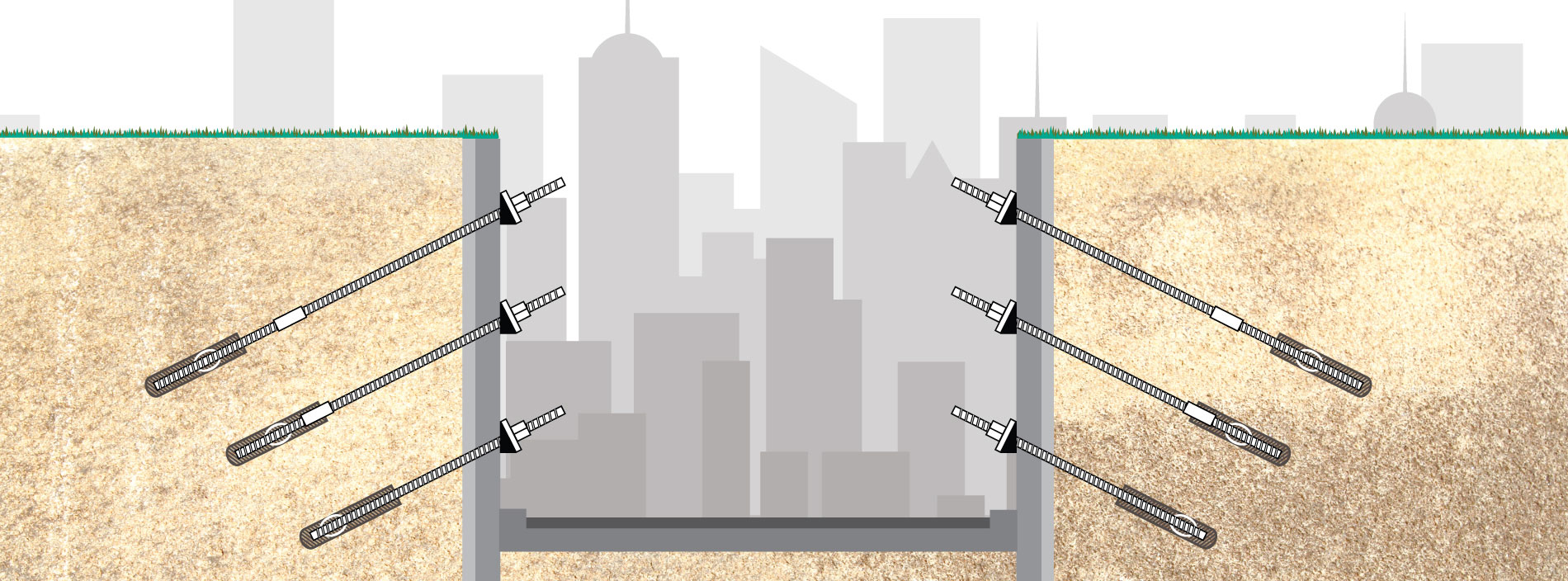

A typical application for Active Anchors is anchoring of retaining walls during excavation works. To prevent the wall from the smallest displacement, the anchor is pre-loaded.

ASTEC Active Anchors is made of composite material, which is by nature cut-able. The tendons can be excavated by any standard equipment, therefore anchor removal is never required.