Soft-Eyes

Soft-Eyes

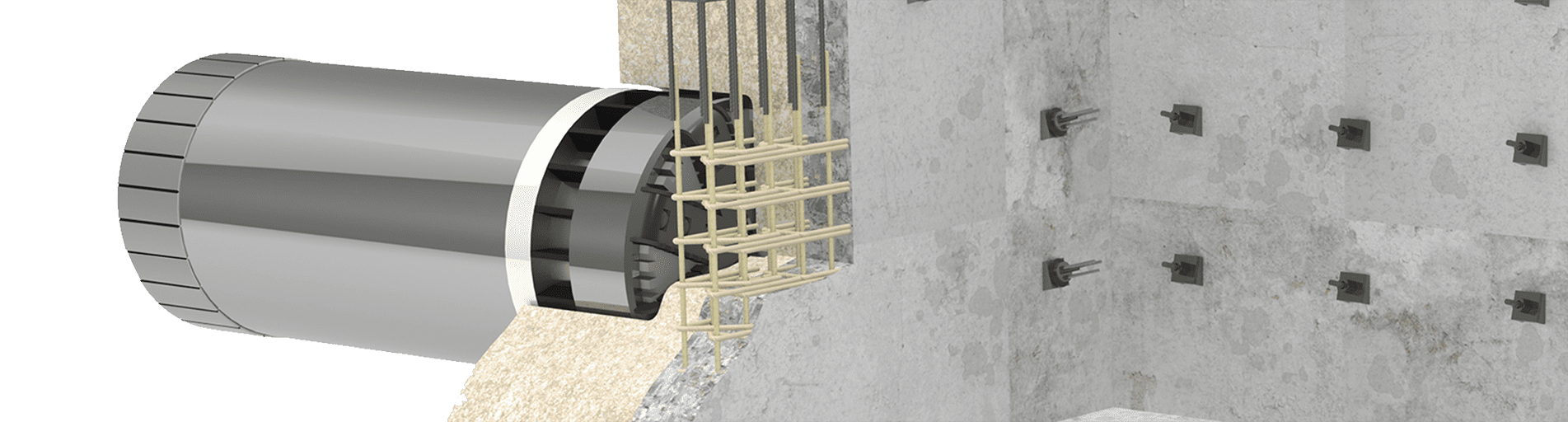

Tunnel breakthrough made easy with FRP rebar

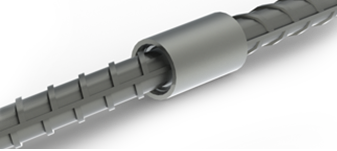

ASTEC Soft–Eyes allow the penetration of Tunnel Boring Machines (TBM) through diaphragm walls and secant piles. This unique technology uses cut-able Glass Fiber Reinforced Polymer (GFRP) reinforcement as an advantageous replacement for conventional steel rebars.

The Soft-Eye technology has been developed by Dextra in 1996 and successfully implemented for the first time on Bangkok MRT subway stations. The Soft-Eye technology has since become a standard concept in the design of launching/receiving shafts and subway stations. We have successfully supplied over 500 soft-eyes on all continents.

Dextra offers an integrated turn-key solution which includes design, optimization, manufacturing, logistic and on-site training.