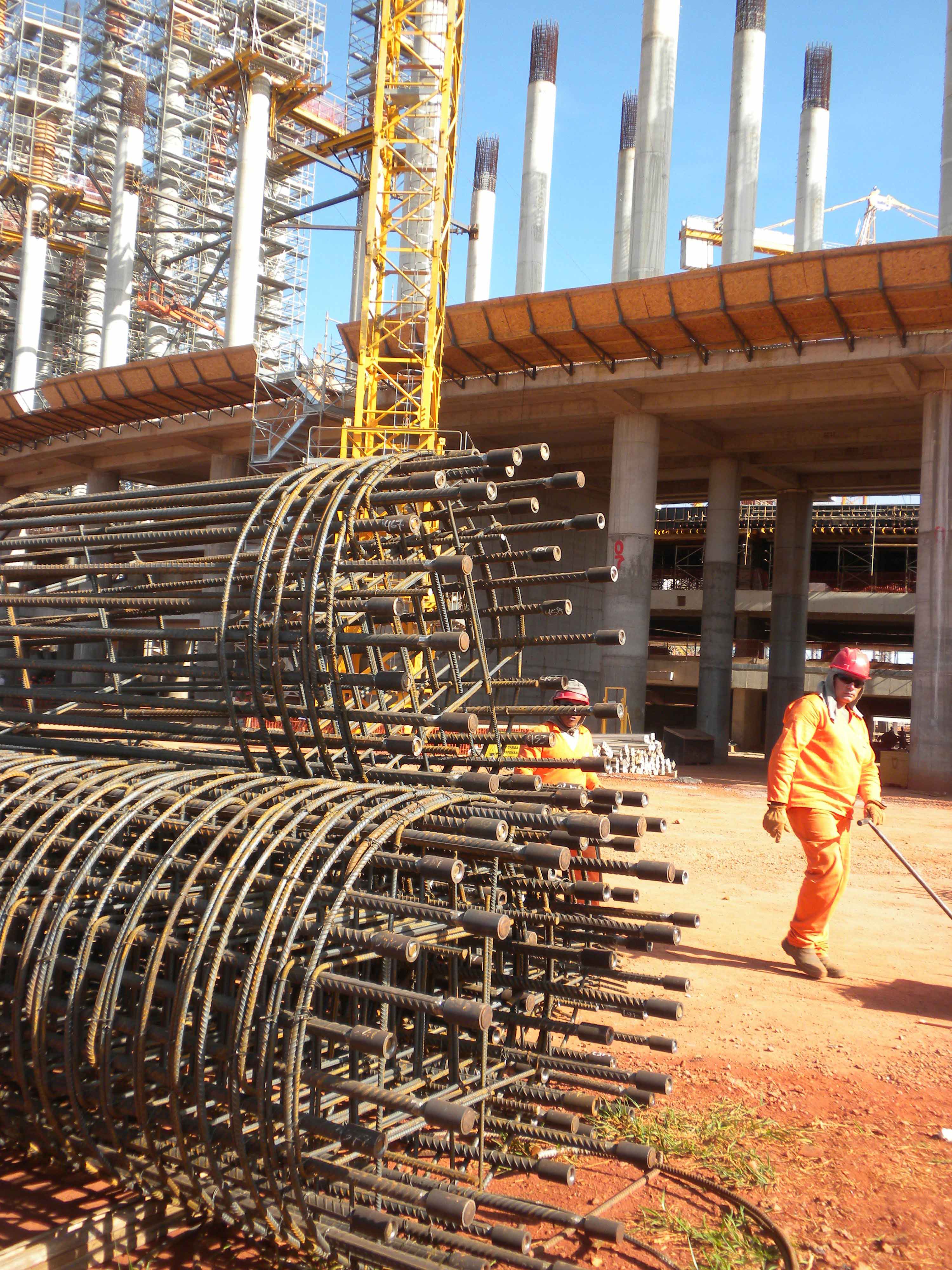

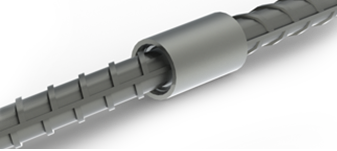

Light and productive rebar coupler solution

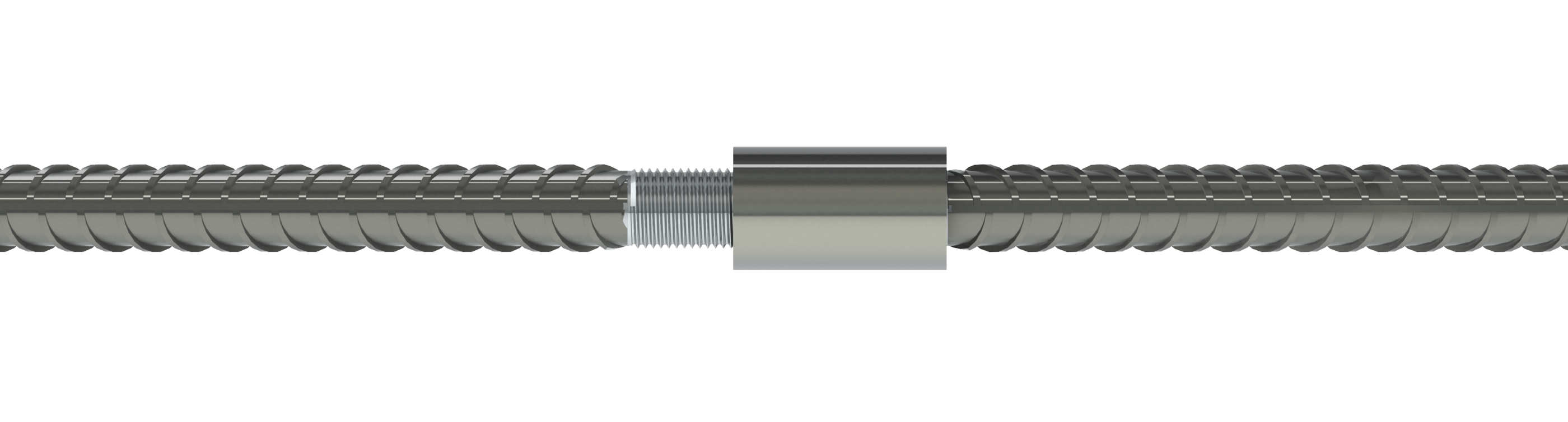

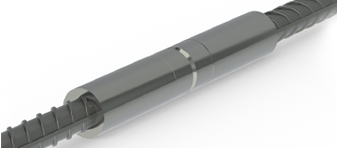

Rolltec® is a rolled-parallel threaded mechanical splicing system designed for the connection of concrete reinforcing bars from Ø12 to 50 mm (ASTM #4 to #18).

Rolltec® solution is supported by a single rebar preparation equipment, which is operated by a single operator.

Rolltec® couplers comply with ACI 318, IBC 2006, BS 8110, Eurocode 2, DIN 1045, CalTrans, ASME Sec III Div 2.