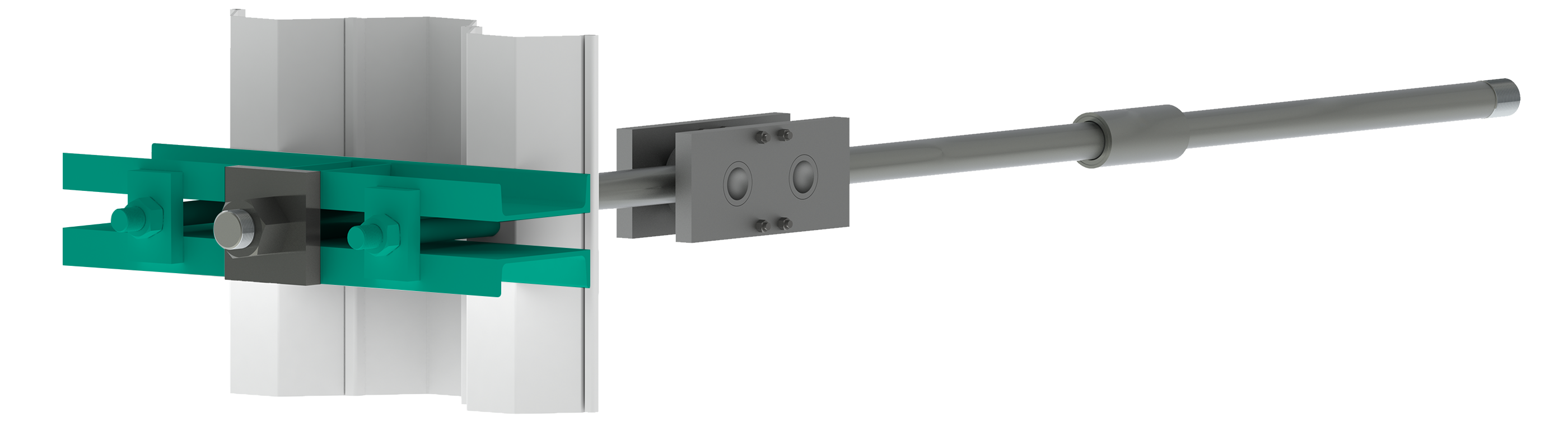

Waling beam systems

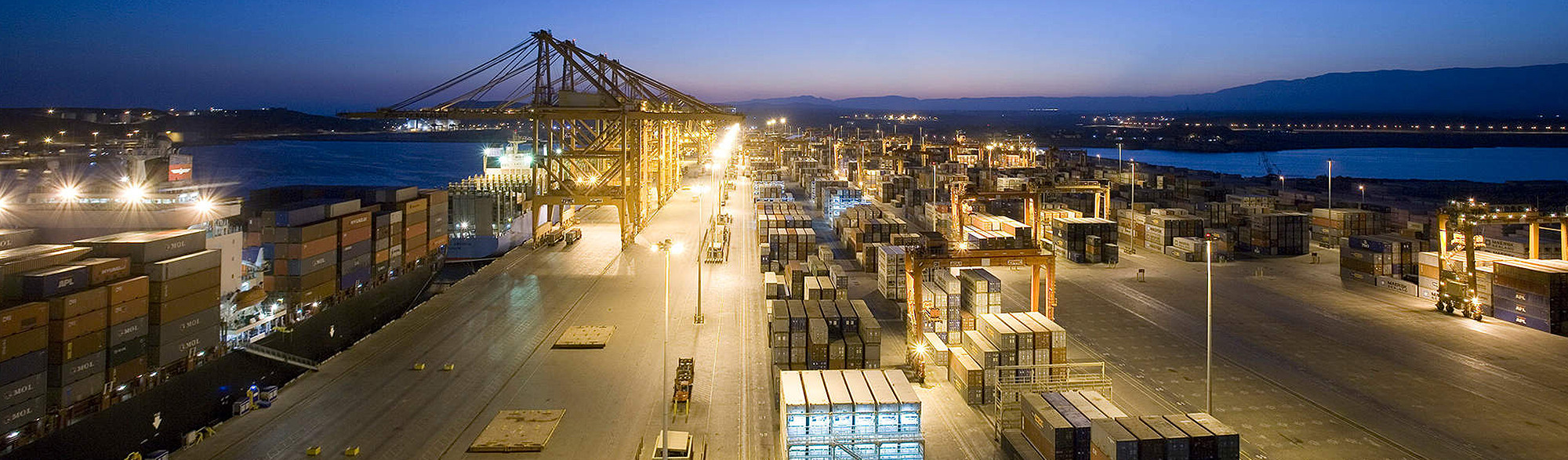

Steel system installed on sheet pile walls

Waling beams are used in combination with tie bars for anchoring sheet pile walls. They allow to spread the load on sheet pile and to concentrate them onto the tie bars.

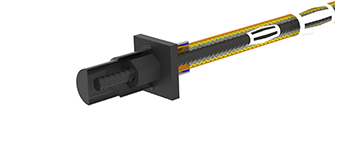

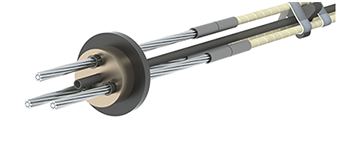

Waling beams and tie bars therefore form a system with strong compatibility with one another.

Whenever possible, Dextra strongly recommends that waling beam and marine tie bars be designed together by Dextra to optimize performance, compatibility and simplify project management.