Micropile systems

Micropile systems

Compact mini-pile system based on FT bars

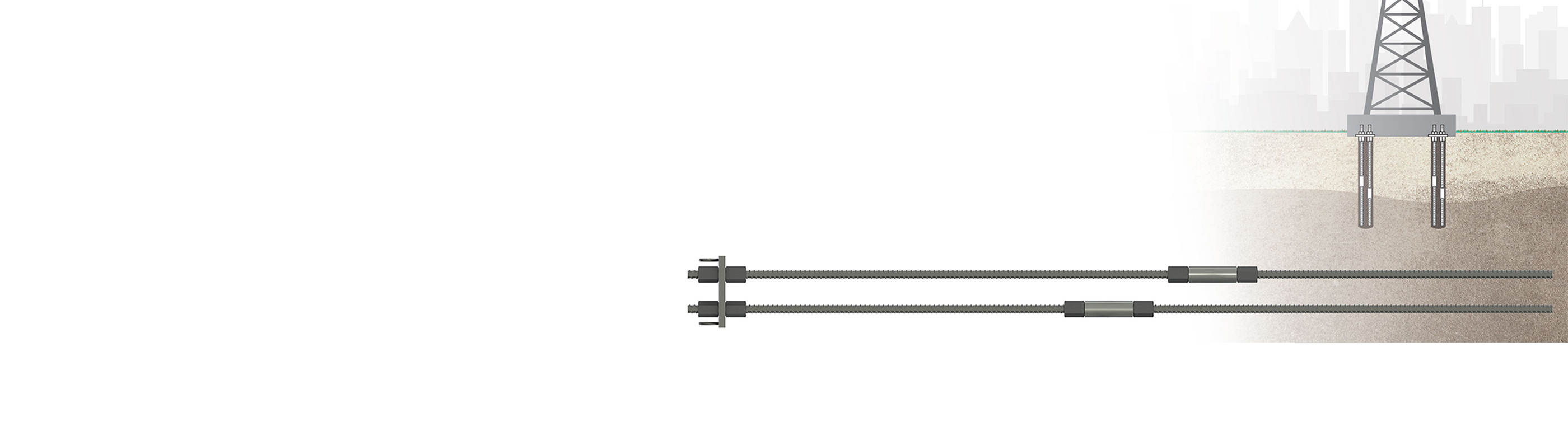

Also known as minipiles, micropiles are deep foundation elements made of high strength, small-diameter steel casing and/or threaded bars.

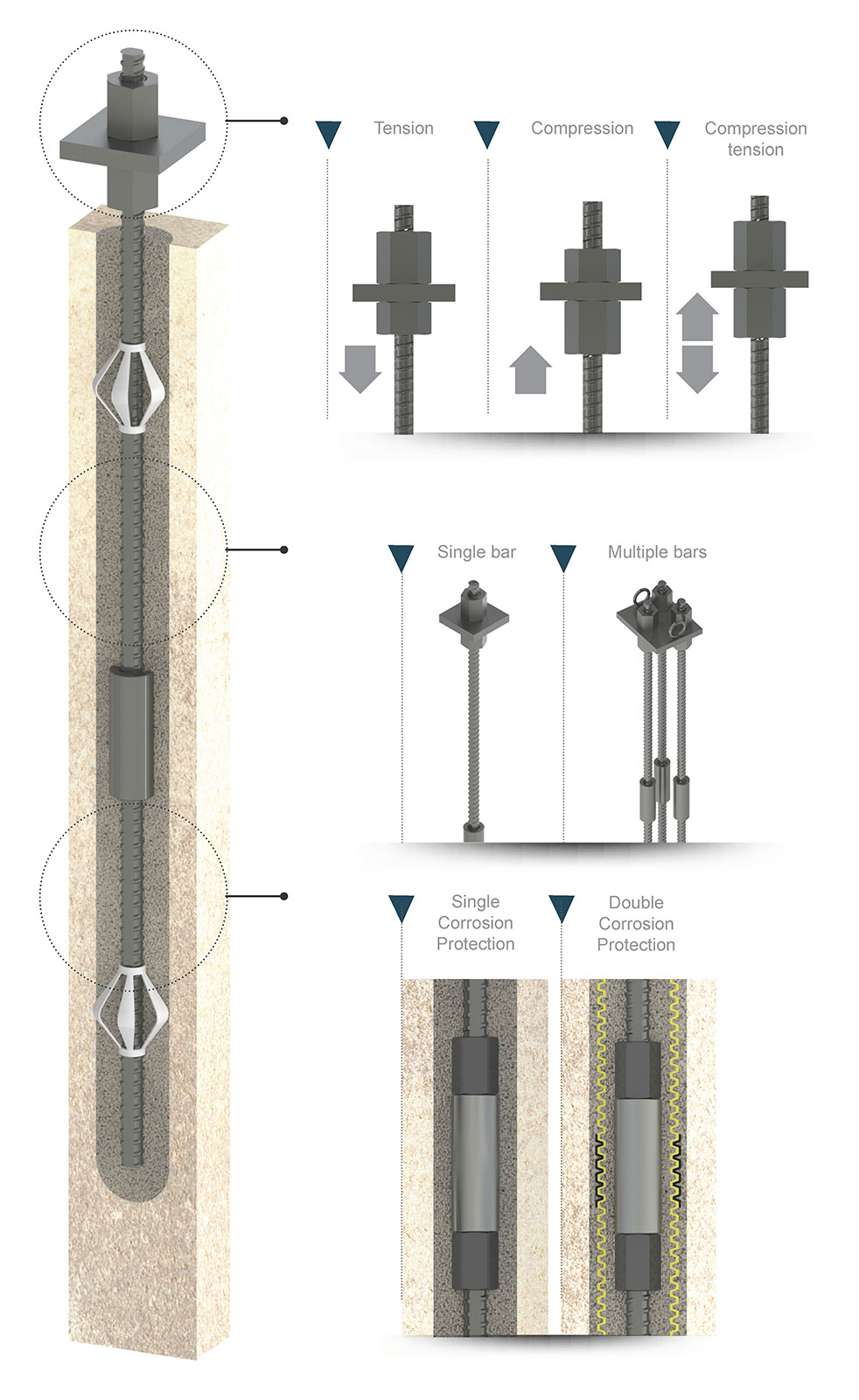

Micropiles can be used as a temporary or a permanent solution. They can work in tension, compression or both.

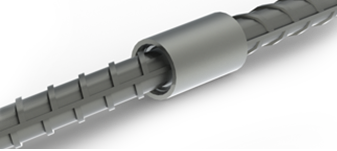

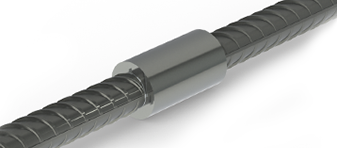

This page focuses on the Geotec Micropile systems, which is based on high-performance fully threaded steel bars.

If your project plans on using cages of standard rebar for micropiles instead of high-performance steel, please refer to our Rebar Coupler system page for more information on thread and coupler systems.