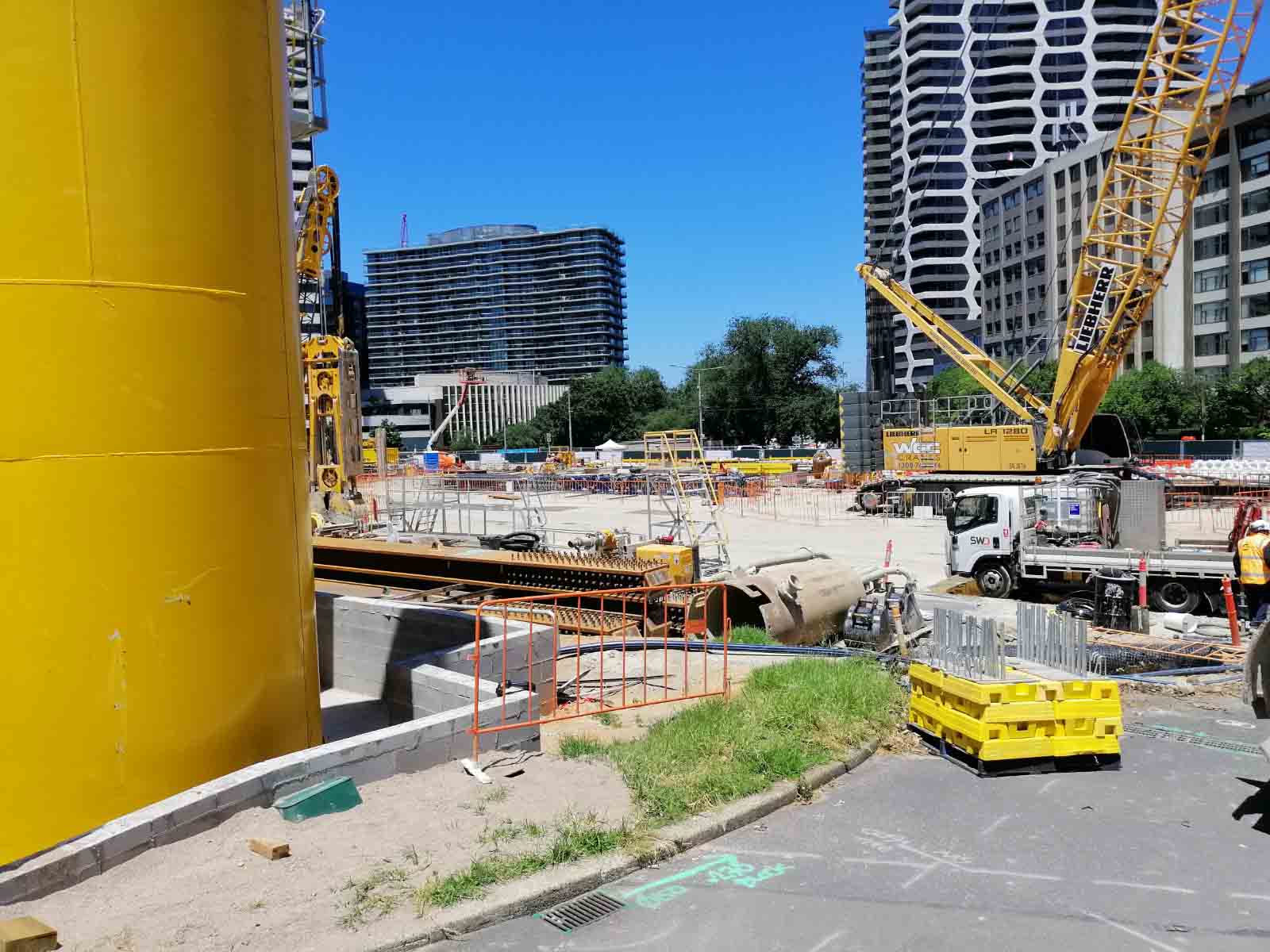

Melbourne Metro: five new underground stations

The Melbourne city's metropolitan rail service operates 226 six-carriage trains across 998 km of tracks. The Metro has 15 lines and 222 stations, serving more than 400,000 passengers a day across the city.

In 2017, the construction of a 9 km long tunnel and five new underground stations were announced for greater capacity and additional coverage of the suburban area of the city.

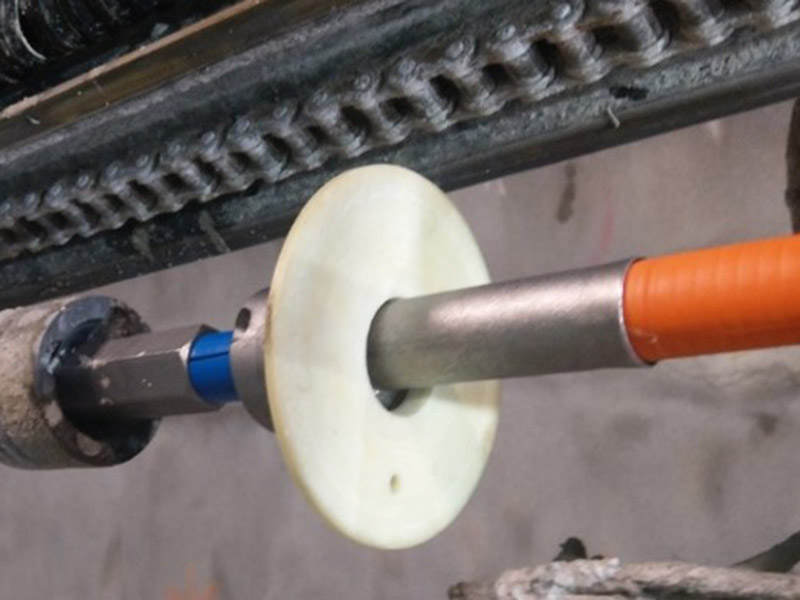

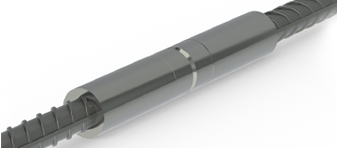

The construction started in 2018. Dextra was involved in the project by supplying rebar connectors with fully automated rebar preparation equipment for the stations’ structure reinforcement works.

Griptec couplers were chosen thanks to the unrivaled performance in tension, compression and fatigue, and 400,000 units have been delivered.

Moreover, Dextra also supplied:

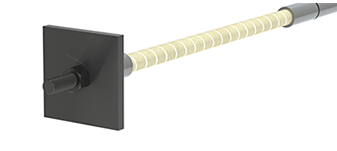

- 5,300 GFRP Astec Combination Bolts. It is used at the CBD cavern location. The 19m width of the cavern allowed for the construction of two conventional 7m tunnels, built in parallel with the middle segments secured by GFRP CB Bolts, that can be cut to make the gallery wider.

- 2,400 GFRP Geotec GR45 - 25mm dowels of 11.8 meters long were used to secure the face during the excavation.

- 900 GFRP Astec soil nails ST50 - 41 were applied to secure several stations under construction. Some of them are outside of the boundary of the project since the GFRP can remain on the ground outside of their property and can easily be cut later.

- 16 soft eyes were used in d-wall and bored pile of five stations.

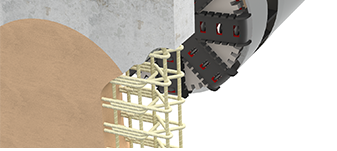

Dextra was able to support and share their expertise on GFRP at design stage and produce the GFRP shaped solutions as per the owner expectation. Thanks to the cuttability of the GFRP, the TBM can pass through the d-wall in a limited time without any damages.

The Metro tunnel and its new stations are due to open in 2025 and predicted to be a new landmark of the city.

(photo credit: Hugh Llewelyn at https://bit.ly/2S0kbAG)