Hinkley Point C Nuclear Power Plant

The Hinkley Point C (HPC) nuclear power station is one of the biggest and most technologically complex projects in Europe.

HPC is the first nuclear power station to be built in the UK in a generation, and its construction requires a highly skilled workforce and the very best construction and engineering solutions.

The HPC Project is located in Somerset, South West England, and will consist of two nuclear reactors capable of generating 3.2GW of low-caron electricity.

The new power station is being constructed in the same area as the existing Hinkley Point A and B stations. The former has ceased operation for quite some time, while the latter is scheduled to be begin decommissioning in 2023.

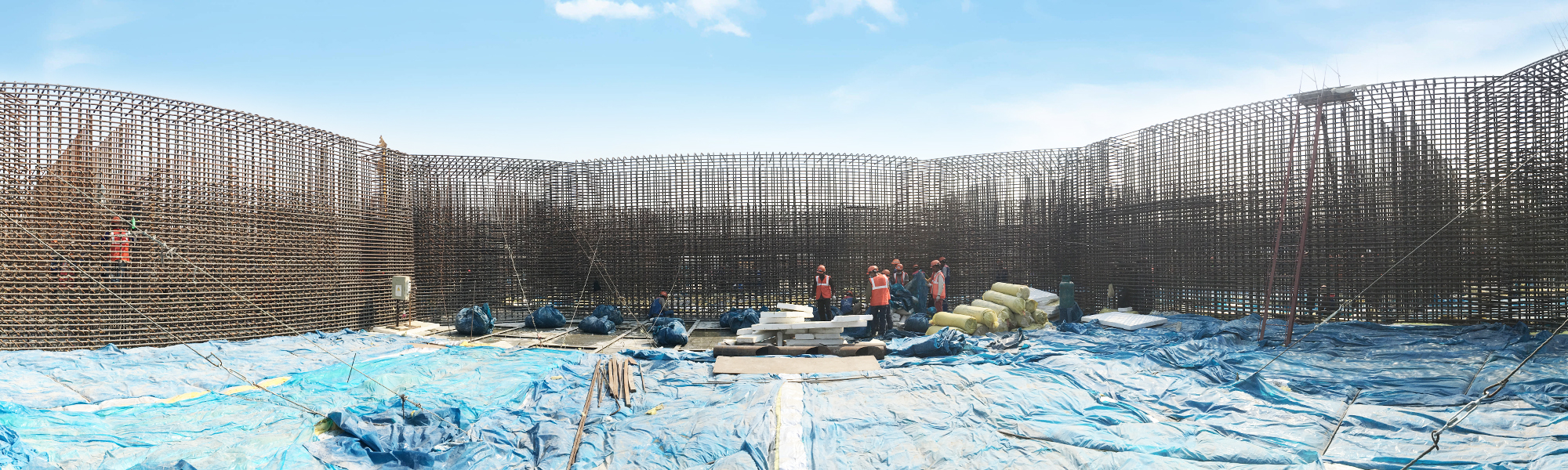

Dextra was entrusted with the supply of mechanical splices of concrete reinforcement for parts of HPC, particularly the reactor’s aircraft impact protect shell.

More than one million Griptec couplers are forecasted to be required for the construction of HPC.

Griptec is designed to comply with the most stringent project specifications, and has proven to be a popular system of choice for EPR nuclear power stations, having been used for the construction of the Flamanville 3, Taishan 1 and Taishan 2 power stations.

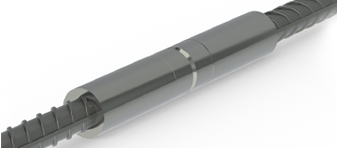

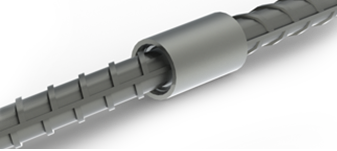

The Griptec mechanical splice consists of two steel sleeves which are swaged onto the end of the reinforcing bars by a specific machine which was designed and patented by Dextra.

This swaging machine incorporates a systematic non-destructive pull test. Griptec is the only coupler system that provides an automatic quality control of each processed bar.

Beside Griptec couplers, Dextra is also supplying headed links to the project. These are reinforcing bars that are bent on one side and fitted with an anchorage head on the other side and are used for the transverse reinforcement of concrete slabs, rafts and walls. They allow a much faster and safer site installation than the conventional double-bends bars.

When complete HPC will provide low-carbon electricity for around six million homes.