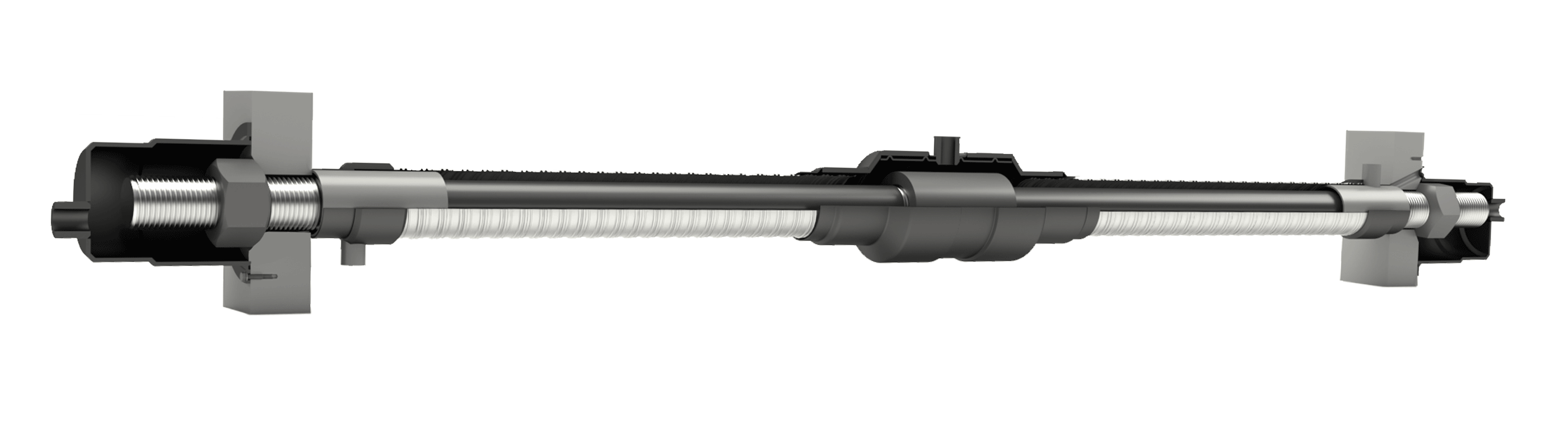

Holding Down Bar Systems

Restraint system for wind turbines

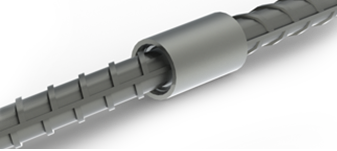

High Tensile Holding Down Bars are a special application for smooth Post Tensioning bar systems for the connection between steel and concrete elements or concrete to concrete elements.

Typical applications include the holding down bars for wind turbines, for the connection of steel pylons to concrete foundations, and for the connection of precast concrete elements.

Each bar tendon is typically terminated via a nut bearing onto steelwork or a steel plate. In order to eliminate bar stretch and hence movement under externally applied loads, the bar is usually tensioned using a hydraulic jack.