Being the new fast-tracks linking the Center to the East of Thailand, the construction of Bang Pa-In – Nakhon Ratchasima Motorway is therefore considered one of the country’s major infrastructure projects.

The main purpose of this project is to stimulate the country’s economy. When completed, it will connect Thailand’s major urban centers within the Greater Mekong Sub-region.

The Intercity Motorway includes two sections: the six-lane 103-kilometer section from Bang Pa-In to Pak Chong, and the 93-kilometer four-lane from Pak Chong to Nakhon Ratchasima. Having been started in 2016, the project is planned to last until 2020.

The project’s required completion period of 4 years being challenging, the construction of the motorway has been divided into approximately 40 contracts to accelerate the project’s schedule.

To minimize potential impacts to local residents, a number of underpasses, overpasses and elevated structures (e.g. large viaducts) are provided throughout the Bang Pa-In – Nakhon Ratchasima Motorway.

Optimize the infrastructure project with Dextra’s rebar couplers

For the construction of the motorway’s elevated structure, the contractors of different packages opted for Dextra’s full performance Bartec rebar couplers to save time and money on the mechanical connection of the diameter 20mm to 32mm reinforcement bars.

Thanks to Bartec’s unique splicing system, all applications (Standard/ Position) can be fulfilled by one and only model of rebar coupler, reducing inventory management of the project to a minimum.

Further to this, Dextra’s Sonitec sonic tubes were also installed for cross-hole sonic logging tests in the foundations of the Bang Pa-In – Nakhon Ratchasima Intercity Motorway structures.

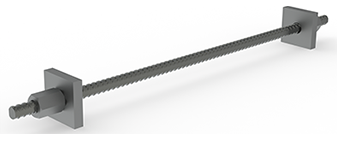

Dextra’s post-tensioning bars for the Motorway’s elevated structures

In addition to Dextra’s splicing and cross hole logging solutions, both smooth and fully-threaded Post-Tensioning bars were also used for both temporary (lifting and launching girder assembly) and permanent applications in segments. Approximately 28,000 sets of both PT bars have been delivered as per June 2018.

For more information about Dextra’s solutions in Thailand, please contact our Bangkok office.