La Hague nuclear waste reprocessing plant – the interim storage

La Hague site is a nuclear fuel reprocessing facilities located in La Hague, northern France. The plant has been treating spent nuclear waste from several countries since 1960s. Nowadays, Being operated by AREVA NC, it now operates nearly half of the world’s spent nuclear fuel recycling and reprocessing capacity, including waste from France itself, as well as from Japan, Germany, Belgium, Switzerland, Italy, Australia, Spain and the Netherlands. The reprocessing plant also separates waste of different radioactive activity and life span, and applies specific storage solutions to each type of waste. Therefore, in order to reassure the reinforcement of the plant’s two recent nuclear waste storage, the main contractor VINCI – Travaux Public Cherbourg opted for Dextra’s 100%-proofed splicing system Griptec, delivered through its local fabricators in France.

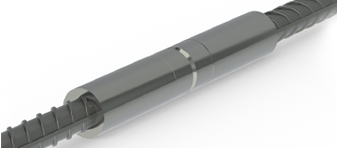

Griptec, full performance rebar couplers for nuclear projects worldwide

For the construction of nuclear projects, full-performance reinforcement solutions are required. This is the reason why Dextra Griptec was preferred for this project, as it is also certified AFCEN, the international standard for nuclear plants. More than 5,000 tons of Dextra products were delivered on-site for the construction of two storage buildings, both intended to store Uranium and Plutonium. Griptec couplers are used to reinforce the storages’ walls, as it is a full-performance (tension, compression, cyclic and fatigue) rebar splicing system. The solution provides no place for error, as each and every connection is systematically proof-tested by pull test during extrusion cycle as part of its standard cycle, and can perform above the project requirement. Moreover, for our customers in nuclear industry, Dextra provides more than only reinforcement solutions: we also accompany designers, consultants and contractors through each step of their construction project.

For more information about our solutions available in France and in Europe, please contact our Paris office.