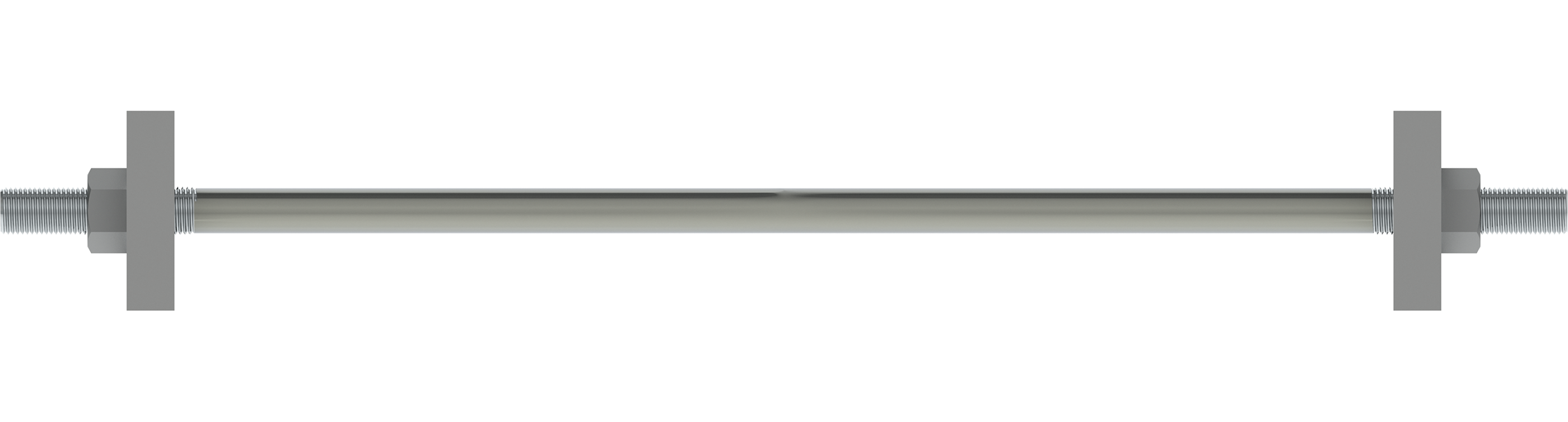

Smooth PT bar systems

High-performance Post-Tensioning solution

Dextra’s Post Tensioning Bar Systems can be used for a variety of temporary and permanent construction applications.

Typical permanent applications include the connection of girders and piers in segmental bridge construction.

Temporary uses include heavy lifting, pre-loading, stitching and anchoring of steel frame supports.

Dextra PT range is divided in two major type of bars. This page focuses on the PT Bar systems using smooth high performance carbon steel bars with threaded ends, which are prepared to length as per project requirements.